Revolutionizing the Way We Create and Wear Jewelry

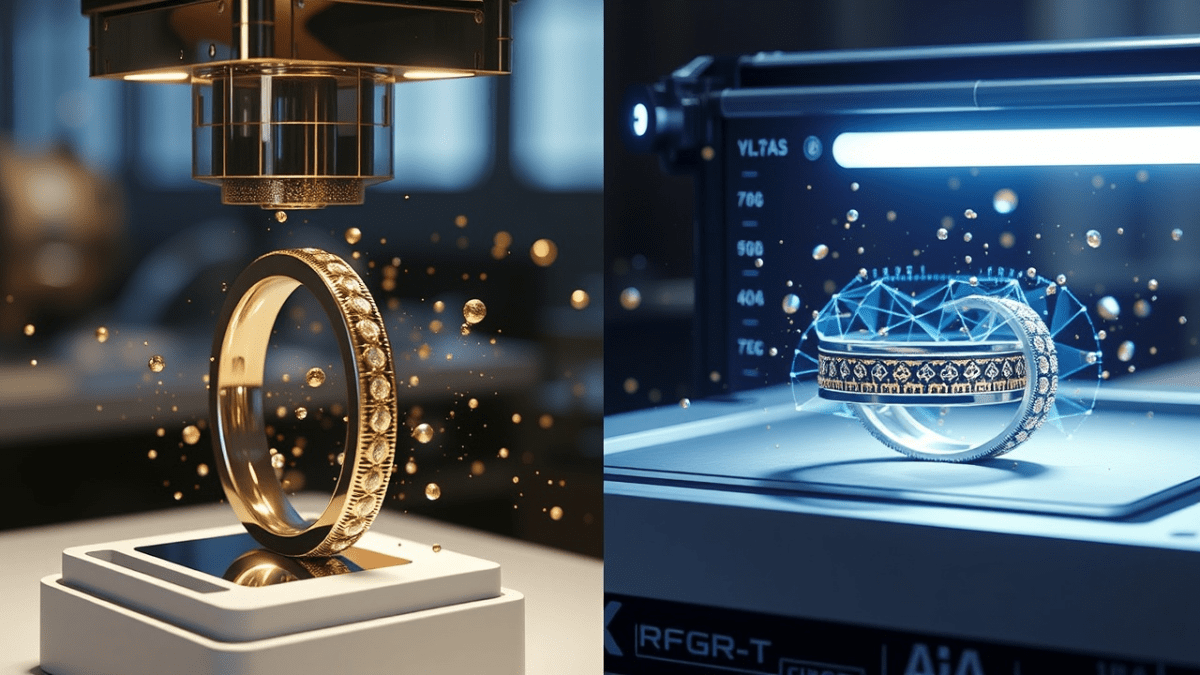

The world of jewelry design has undergone a remarkable transformation with the advent of 3D printing technology. This revolutionary approach has not only streamlined production processes but has fundamentally changed how we conceptualize, create, and customize jewelry pieces. From rapid prototyping to mass customization, 3D printing is reshaping the future of jewelry manufacturing.

The Technology Behind 3D Printed Jewelry

Advanced Printing Materials and Methods

Recent studies show that the 3D printed jewelry market is expected to reach $7.6 billion by 2026, with a CAGR of 20.5% between 2021-2026. This explosive growth is driven by innovations in printing materials and methods.

- Primary Materials Used in 3D Printed Jewelry:

- Precious Metal Powders (Gold, Silver, Platinum)

- Castable Resins

- Wax-like Materials

- Bio-compatible Polymers

Learn more about sustainable jewelry trends →

Design Software and Digital Tools

The marriage of CAD software with 3D printing has created unprecedented opportunities for jewelry designers. According to industry surveys, 78% of jewelry designers now incorporate some form of digital design tools in their workflow.

Steps Explained

-

Design Concept: The process begins with an initial idea or concept for the jewelry piece. This stage is crucial as it sets the foundation for the entire design.

-

CAD Modeling: Once the concept is established, designers use CAD (Computer-Aided Design) software to create detailed 3D models of their designs. This allows for precision and the ability to visualize the piece before it is produced.

-

Digital Optimization: After modeling, the design undergoes digital optimization to ensure it is suitable for 3D printing. This may involve adjusting dimensions, refining details, and ensuring structural integrity.

-

Prototype Printing: With an optimized model, designers can create a prototype using 3D printing technology. This step enables them to evaluate the design in a tangible form and make any necessary adjustments.

-

Material Selection: Once the prototype is approved, designers select appropriate materials for the final piece. This choice can significantly impact the aesthetics and durability of the jewelry.

-

Final Production: The last step involves the actual production of the jewelry piece, where the finalized design is crafted using the selected materials, completing the design journey.

By leveraging these digital tools, jewelry designers can enhance their creativity, streamline their workflows, and produce high-quality pieces that meet the demands of modern consumers.

Quality Control and Precision

Modern 3D printers can achieve resolution as fine as 25 microns, enabling intricate details that rival traditional handcrafting. This precision has revolutionized quality control processes.

| Printing Method | Resolution | Material Compatibility | Cost Efficiency |

|---|---|---|---|

| SLA | 25-100 μm | High | Medium |

| DLP | 30-60 μm | Medium | High |

| FDM | 100-300 μm | Low | Very High |

Custom Design and Market Impact

Personalization Revolution

Explore our guide to bespoke jewelry design →

The ability to rapidly prototype and customize designs has transformed the market. Studies indicate that 65% of consumers are willing to pay more for personalized jewelry pieces.

Market Trends and Consumer Behavior

Recent market analysis shows fascinating trends in consumer preferences:

- 82% of millennials prefer customized jewelry

- 73% of buyers want to participate in the design process

- 60% are interested in sustainable manufacturing methods

Discover upcoming jewelry trends →

Cost Analysis and Production Efficiency

3D printing has significantly reduced production costs:

- Traditional Manufacturing vs. 3D Printing:

- 40% reduction in material waste

- 60% faster production time

- 35% lower labor costs

Future Innovations and Sustainability

Emerging Technologies

The integration of AI and machine learning with 3D printing is opening new frontiers in jewelry design. Learn about the latest jewelry design software →

Sustainable Practices

Environmental impact reduction through 3D printing:

- 45% less energy consumption

- 60% reduction in carbon footprint

- 90% material recyclability

Explore ethical jewelry production →

Industry Predictions

Expert forecasts suggest that by 2025:

- 40% of all custom jewelry will involve 3D printing

- 30% reduction in time-to-market

- 25% increase in design complexity capabilities

3D printing machine brands commonly used for jewelry production

Here are the top ten 3D printing machine brands commonly used for jewelry production, along with brief descriptions, their locations, and links to their websites if that can help you get started.

1. Stratasys

- Description: A leader in 3D printing technologies, Stratasys offers a variety of solutions for different industries, including jewelry. Their printers are known for high precision and versatility.

- Location: Rehovot, Minnesota, United States

- Website: stratasys.com

2. EnvisionTEC

- Description: Renowned for its high-resolution 3D printers specifically designed for jewelry, EnvisionTEC focuses on castable parts and offers a range of materials for intricate designs.

- Location: Dearborn, Michigan, United States

- Website: envisiontec.com

3. 3D Systems

- Description: One of the pioneers in 3D printing technology, 3D Systems provides advanced solutions tailored for jewelry manufacturing, emphasizing quality and detail.

- Location: Rock Hill, South Carolina, United States

- Website: 3dsystems.com

4. Phrozen Technology

- Description: Known for its high-resolution resin printers like the Sonic Mini 8K, Phrozen specializes in creating detailed jewelry models with exceptional surface quality.

- Location: New Taipei City, Taiwan

- Website: phrozen3d.com

5. Elegoo

- Description: Elegoo produces cost-effective resin printers that are popular among jewelers for their ability to create fine details and intricate designs efficiently.

- Location: Shenzhen, China

- Website: elegoo.com

6. Formlabs

- Description: Formlabs is well-known for its SLA printers that deliver high-quality prints suitable for jewelry applications. Their machines are user-friendly and designed for small businesses.

- Location: Somerville, Massachusetts, United States

- Website: formlabs.com

7. Anycubic

- Description: Offering a range of affordable resin printers, Anycubic is favored by hobbyists and professionals alike for producing detailed jewelry pieces without breaking the bank.

- Location: Shenzhen, China

- Website: anycubic.com

8. Creality

- Description: Known primarily for FDM printers, Creality also offers resin options that can be effectively used in jewelry making, providing good quality at competitive prices.

- Location: Shenzhen, China

- Website: creality.com

9. B9Creations

- Description: B9Creations specializes in high-resolution DLP printers designed specifically for the jewelry industry, focusing on speed and detail in production.

- Location: Rapid City, South Dakota, United States

- Website: b9creations.com

10. XYZprinting

- Description: Offering a variety of affordable 3D printers suitable for various applications including jewelry design, XYZprinting is known for its user-friendly machines.

- Location: Taipei City, Taiwan

- Website: xyzprinting.com

These brands represent some of the most trusted names in the industry when it comes to producing high-quality jewelry through 3D printing technology.

Conclusion

The 3D printed jewelry manufacturing process represents a paradigm shift in the industry, combining traditional craftsmanship with cutting-edge technology. As we look toward the future, the continued evolution of 3D printing technology promises even greater innovations in design possibilities, sustainability, and customization options. The marriage of artistry and technology in jewelry manufacturing is not just a trend but a transformation that will continue to shape the industry for years to come.